There are two types of crystalline silicon solar panels, polycrystalline and single crystal, and many people can’t tell the difference between the two, which often makes them difficult to buy. So, what are panel polycrystal and single crystal? Solar photovoltaic panel manufacturers today for you to explain the difference between solar panel polycrystal and single crystal, to understand it together.

First, appearance difference

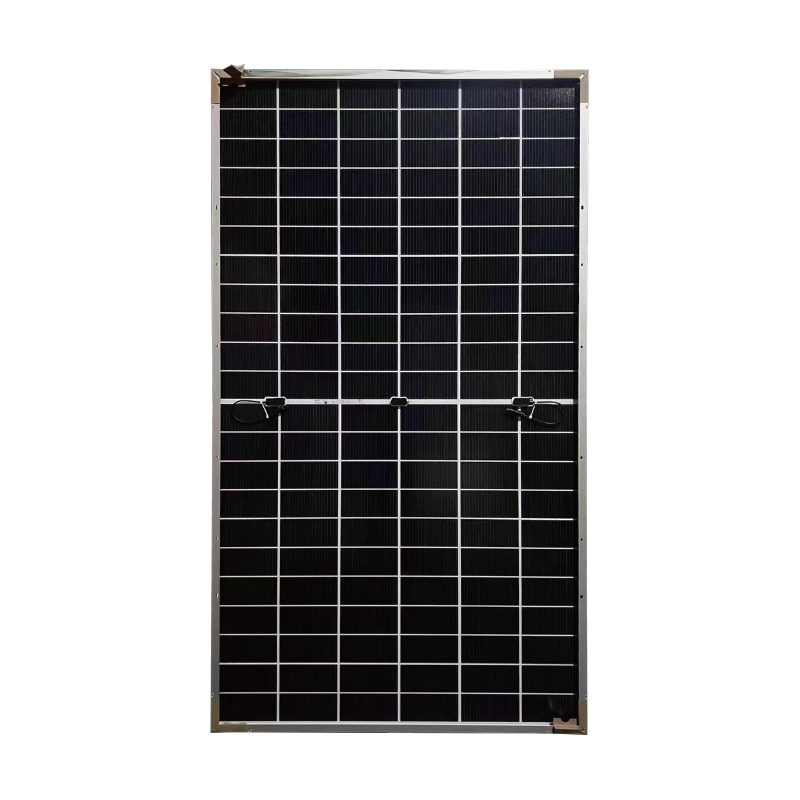

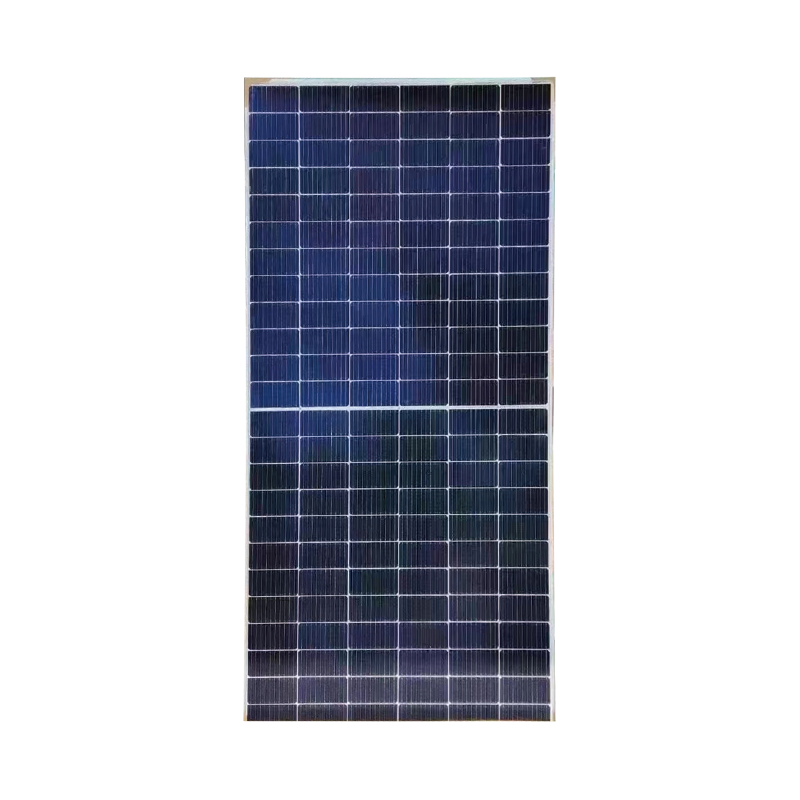

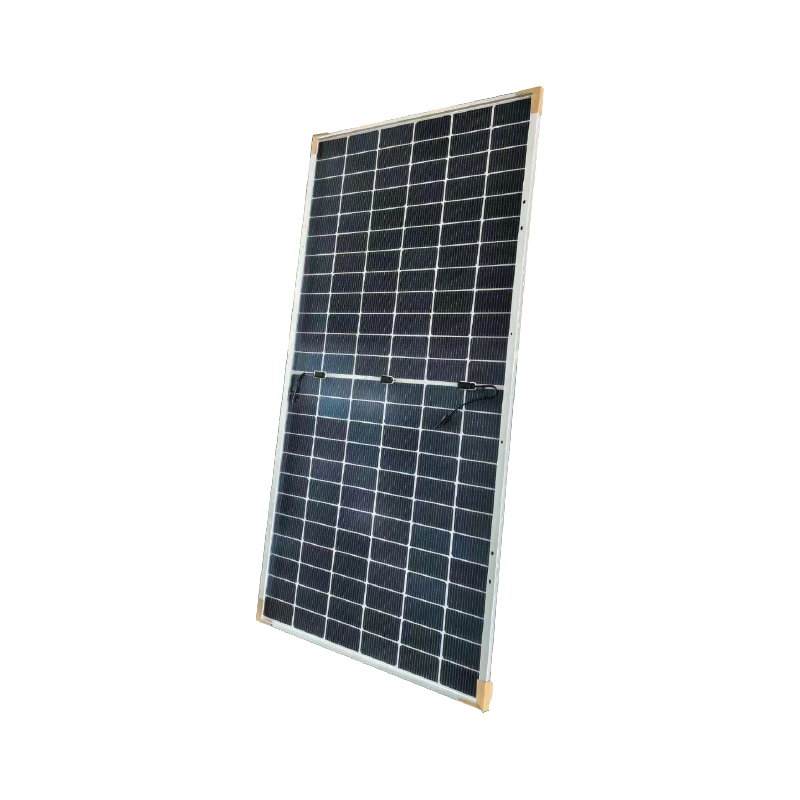

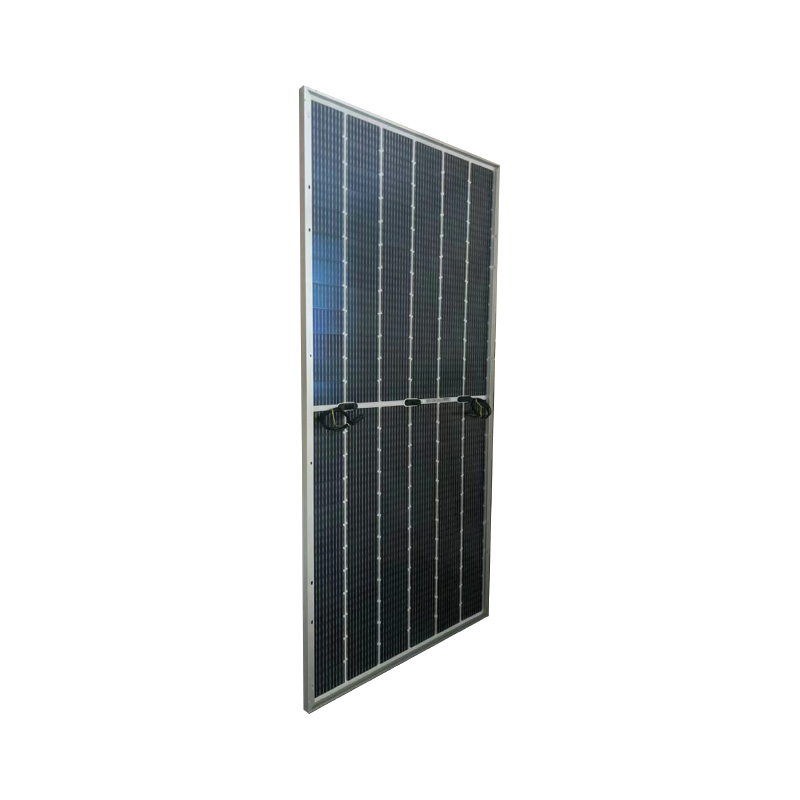

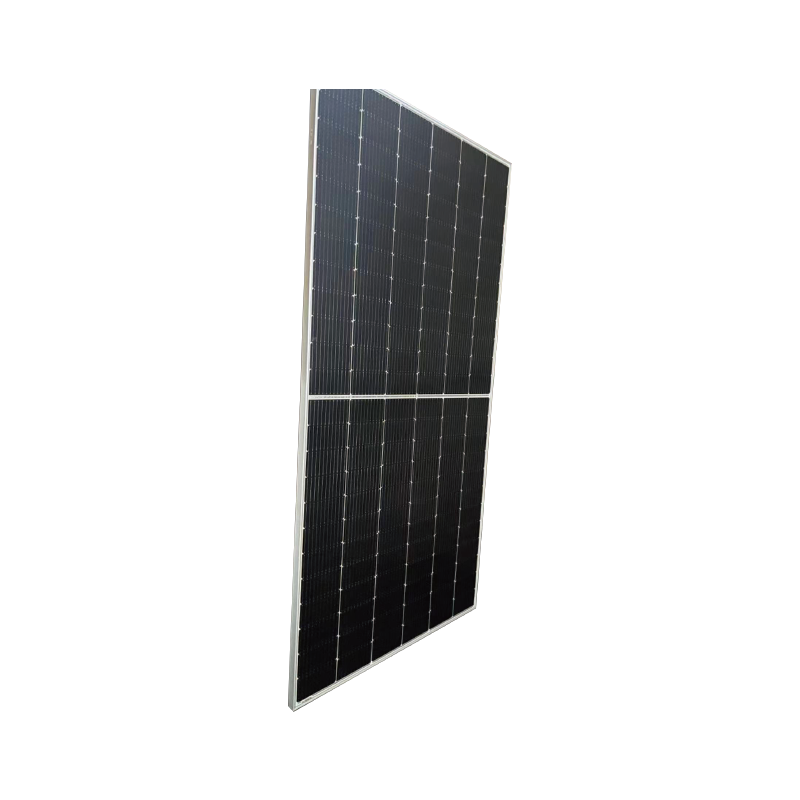

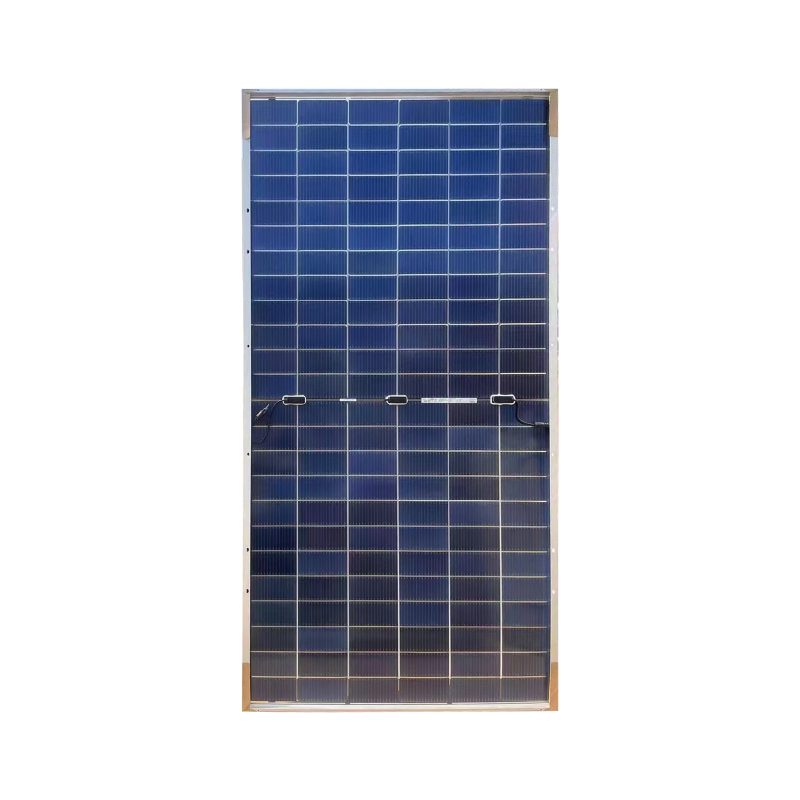

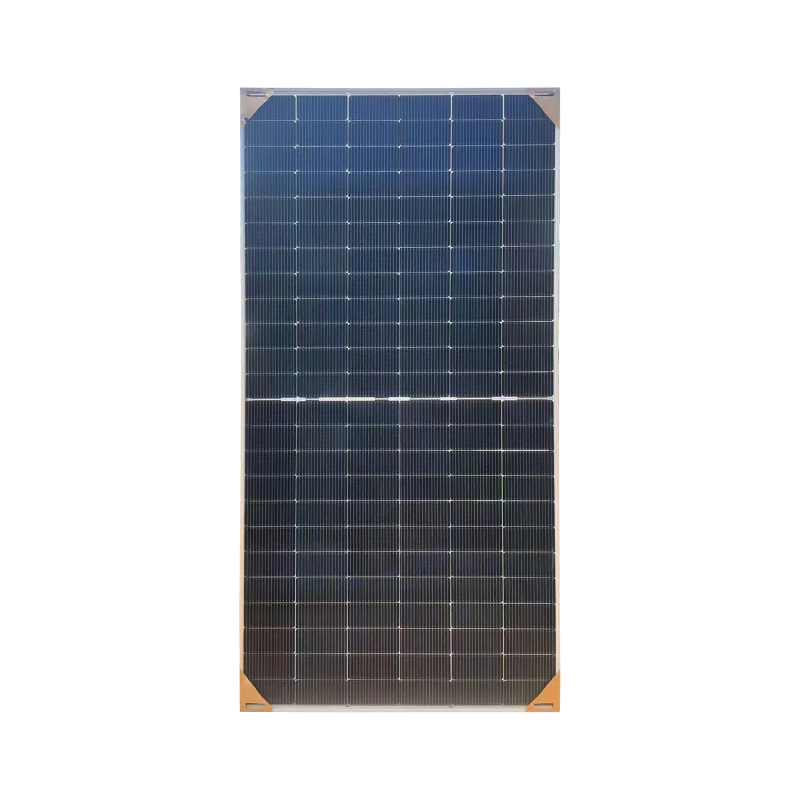

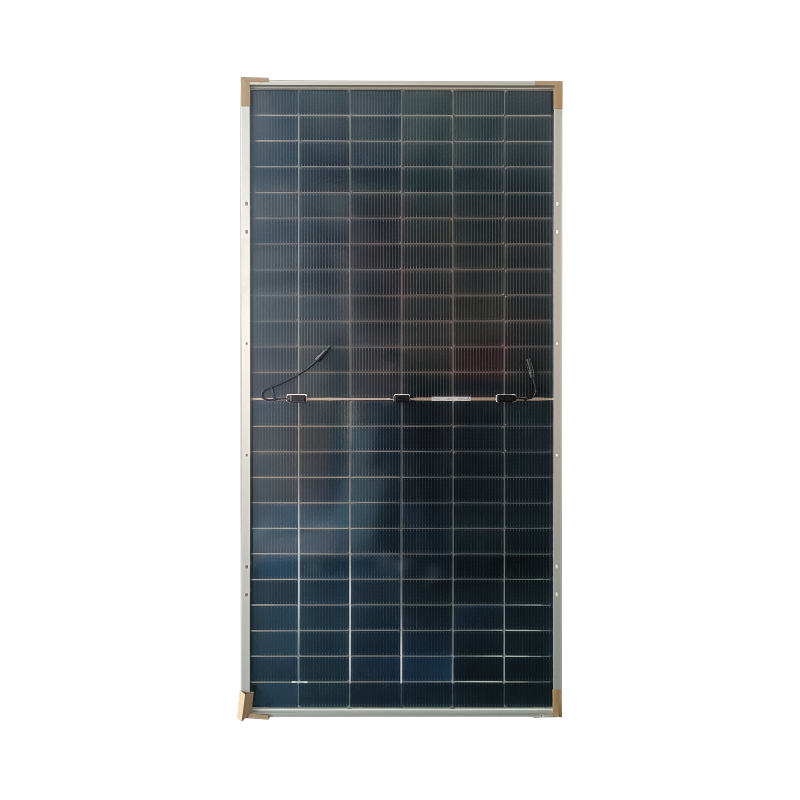

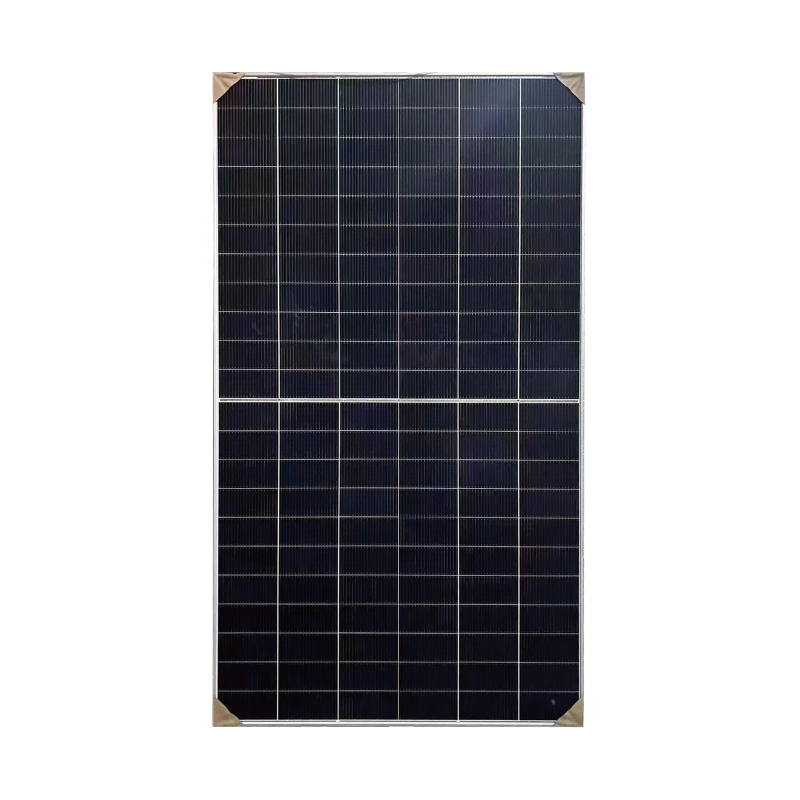

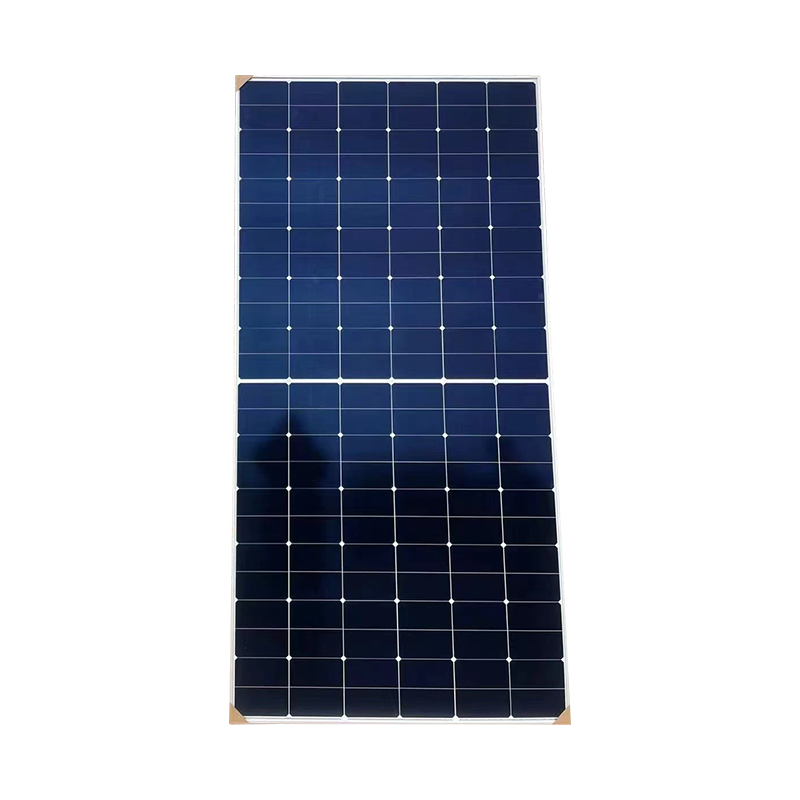

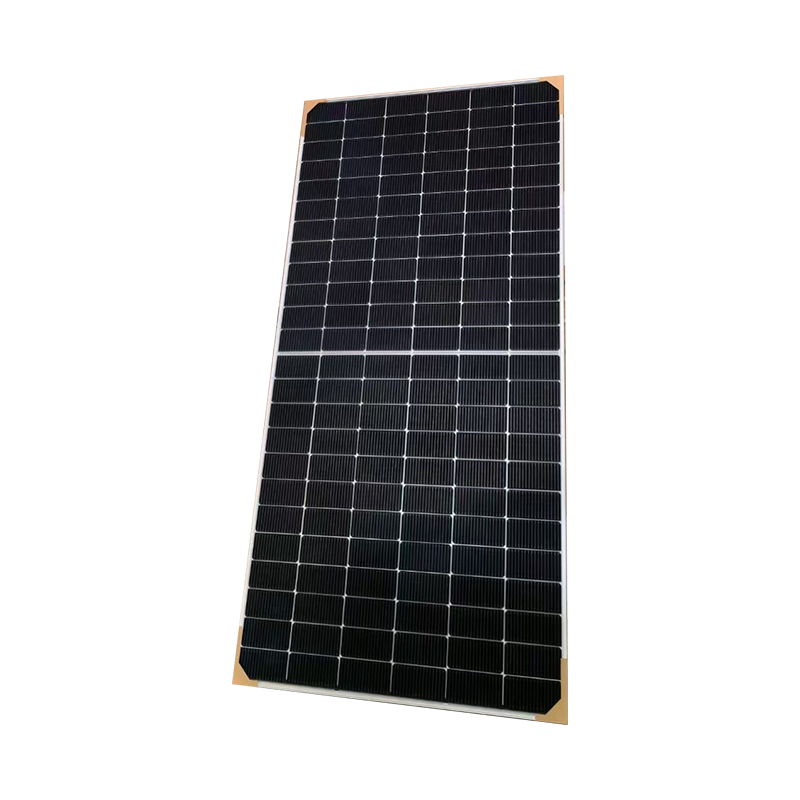

From the appearance of the word, the four corners of the single crystal panel appear circular arc, no surface pattern. Single crystal panels all look the same on the surface. The four corners of the polycrystalline panel show square Angle, there are patterns, polycrystalline and polycrystalline less color, like the snow crystal pattern on the snow sheet, light blue. The surface of the polycrystalline panels looks like there is a lot of broken glass inside, shining.

Two, manufacturing process difference

Monocrystalline silicon and polycrystalline silicon of the difference between their atomic structure arrangement, single crystal is orderly arrangement, polycrystalline is disordered arrangement, this is mainly decided by their processing technology, polycrystalline casting method is used to produce more, is the silicon material in crucible melting, directly to the Siemens modified czochralski method and single crystal is adopted to draw process is a process of atomic structure reorganization.

Polycrystalline solar panels use about 30% less energy to make than single-crystal solar panels, so they account for a larger share of global solar panel production and are less expensive to make than single-crystal solar panels.

Three, the use of distinction

Single crystal solar panel is a kind of solar cell developed quickly at present. Its composition and production technology have been finalized, and the products have been widely used in space and ground facilities. The solar cell is made of high purity monocrystalline silicon rod with purity of 99.999%. The photoelectric conversion efficiency of single crystal solar panel is about 15%, and the high one is 24%. This is the highest photoelectric conversion efficiency among the current kinds of solar cells, but the production cost is very high, so that it can not be widely and widely used. Because the single crystal panel is generally packaged with toughened glass and waterproof resin, it is rugged and durable, with a service life of up to 15 years and up to 25 years.

Although the average conversion efficiency of single crystal panels is about 1% higher than that of polycrystalline panels, but because the single crystal panels can only be made quasi square (four sides are arc-like), so when composed of solar panels, there will be a part of the area filled; Polycrystals are square, so there is no such problem. The photoelectric conversion efficiency of polycrystalline solar panels is about 12%. From the production cost, compared with the monocrystalline silicon solar cells to some, the material manufacturing is simple, saving power consumption, the total production cost is low.

The above is a small series for you to explain the difference between the solar panel polycrystal and single crystal, I hope to help you have more understanding of the two kinds of solar panels. For users, there is no big difference between single crystal panels and polycrystalline panels. Their life and stability are very good. We can choose photovoltaic solar panels with higher comprehensive income according to our actual use.